Bearing metal / white metal for Plain Bearings of international standards

We offer Bearing metal and white metal alloys in delivery forms tailored to your production processes.

Bearing metal / white metal in blocks

Bearing metal white metal round bars

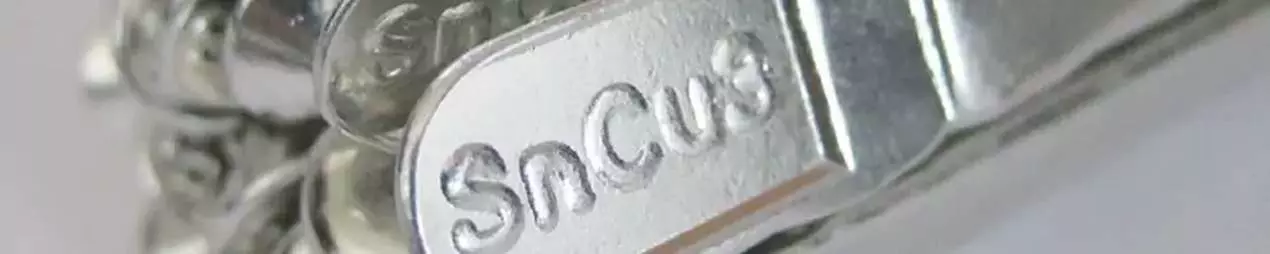

Tin-based white metal and lead-based Bearing metal.

We offer both tin-based white metal and lead-based bearing metals according to common international standards such as EN ISO 4381, ASTM, AFNOR, BS, UNI, etc. or have them manufactured according to your own specifications. We provide white metal alloys in delivery forms tailored to your production processes, whether it is centrifugal casting, static casting, or even soldering for sliding bearing repairs.

Our Bearing metal is available in blocks, bars, rods, and as wire.

Standard alloys include WM89, WM80, WM10, ASTM B23, MB90, MB85, MB80, Code 113. The use of pure raw materials, special refining processes, and modern analysis methods enable the highest quality for your Plain Bearings.

If you are interested in Lagermetall / Weißmetall for Plain Bearings according to international standards, then contact us, we will be happy to advise you.

Did we convince you?

What is bearing metal?

Bearing metal is an alloy of various metals that is used to make bearing sleeves and Plain Bearings. It is a type of non-ferrous metal and is also known as a bearing alloy or white metal. The exact composition varies depending on the application, but typical components are tin, lead, antimony, copper, and zinc.

Bearing metal is in high demand in industry due to its high resistance to wear, corrosion, and fatigue properties. It is used in many applications, such as in engines, transmissions, pumps, and turbines. There are different types of bearing metals that are optimized for specific applications, such as for high loads or for high temperatures.

What is white metal?

White metal is an alloy of tin, antimony, and lead with a high tin content. The exact composition can vary depending on the application, but typically white metal consists of about 80% tin, 15% antimony, and 5% copper.

White metal is a relatively soft, white-colored metal alloy with a low melting point and good castability. Due to its properties, it is often used for the manufacture of bearings, bushings, guides, and other parts that are subjected to high loads.

White metal is widely used in various industrial applications due to its high corrosion resistance, low coefficient of friction, and good wear resistance. It is also used in the jewelry industry, in the hobby sector, and for the manufacture of musical instruments, such as brass instruments.

What is tin-based white metal?

Tin-based white metal is a special type of white metal with a higher tin content than conventional white metal. Typically, tin-based white metal consists of about 90% to 95% tin, 3% to 8% antimony, and 1% to 5% copper.

The higher concentration of tin in the alloy gives tin-based white metal a higher corrosion resistance and better resistance to fatigue and wear than other white metals. It is therefore often used in applications where high loads and extreme conditions occur, such as in high-performance engines, turbines, and other machine components.

Tin-based white metal also has good castability and can be easily cast into complex shapes. It is often used for the manufacture of bearings, bushings, and other components in the automotive, aerospace, and energy industries.

Lead-free high-tin white metals and tin alloys are also used in jewelry making, souvenir making, or handicrafts.

We support you in securing your material needs on the

international commodity markets.

We offer, among other things, bearing metal and white metal, tin alloys, lead alloys, solder / solder wire, Tin sheet / tin discs, pure tin, pewter, as well as alloy metals such as bismuth, antimony, copper, and much more. In order to always offer you fair prices, they are based on the current metal and foreign exchange rates. We are also happy to support you in securing your material needs on the international commodity markets. Please select the desired area of application for detailed information on our products.

The c:met GmbH was founded in 2007 as a young company with a focus on trading tin and lead alloys. As a customer, you can rely on the many years of experience and in-depth metallurgical knowledge of our employees. In our production facility, which is certified according to the latest quality standards, we have access to state-of-the-art manufacturing processes and analytical methods. We offer the metal to you as a raw material as well as further processed as semi-finished products in various delivery forms. We look forward to your inquiries and invite you to test our performance! c:met – your specialist in the trade of tin and lead products.

We offer both tin-based white metals and lead-based bearing metals according to common international standards such as EN ISO 4381, ASTM, AFNOR, BS, UNI, etc. or manufacture them according to your own specifications. We supply white metal alloys in delivery forms tailored to your production processes, whether it is centrifugal casting, static casting, or even soldering for bearing repair.

Tin sheet in two different, lead-free qualities.

As soft pure tin with at least 99.9% Sn or as a harder pewter alloy with the composition Sn95Sb4Cu1. Our Tin sheet is lead-free with Pb max. 0.04% and is used, among other things, in medical technology, as a filter in radiation technology, in organ building, or as an elegant surface for bar counters and countertops. Due to its low melting point and easy workability, the possible applications of Tin sheet are very diverse.

Did we convince you?