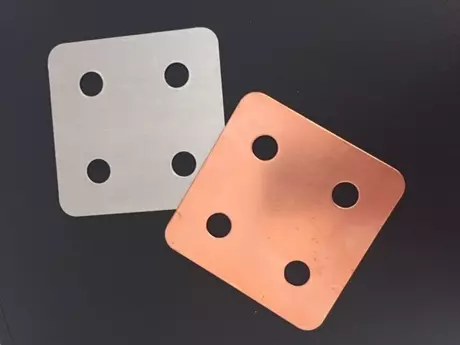

Cupal is a copper cladding on aluminum

The two metals are welded together in a special process.

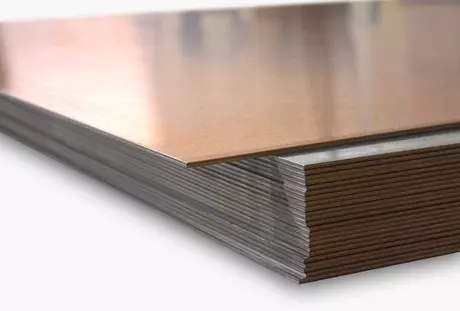

CUPAL is a copper cladding on aluminum. In a special process, copper is welded together with aluminum in an inseparable manner. CUPAL is a composite material (group of non-ferrous metals) and not an alloy. The replacement material CUPAL has been tested for many years and in a variety of applications and has proven itself in place of pure copper and brass.

CUPAL is a cold-rolled composite material between aluminum and copper as a substrate material.

Special properties of CUPAL

CUPAL - Productinformation

The composite material CUPAL is versatile

Manufacturing process of CUPAL

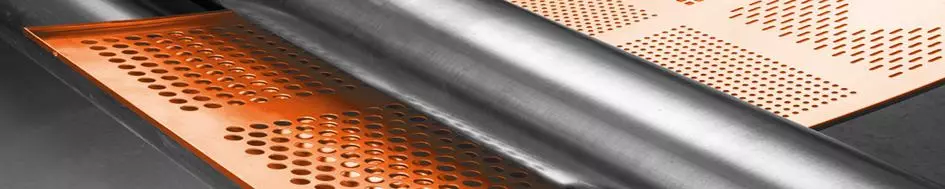

The composite material CUPAL is manufactured by cold-rolled lamination.

After a surface treatment tailored to the respective material, aluminum and copper are firmly bonded together under high pressure in a lamination mill.

The material hardening caused by this must be removed by a suitable heat treatment to achieve the desired properties.

At the same time, the adhesion between aluminum and copper is improved due to diffusion welding.

By limiting the annealing time and temperature, uncontrolled alloy layer formation is suppressed.

Application techniques of CUPAL

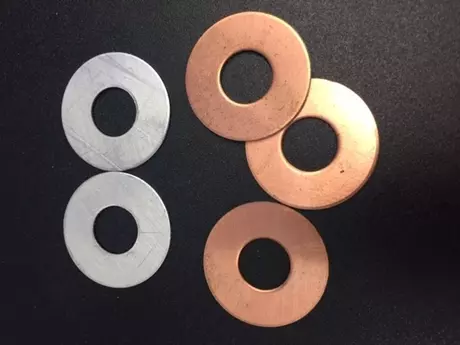

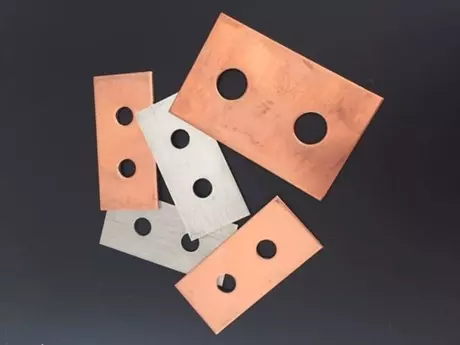

Switchgear and apparatus construction: Use as washers, inserts, and cable lugs

Overhead line construction: Winding band or sleeve-shaped insert in clamping connections.

Advantages of CUPAL: Low specific weight – This results in advantages for accelerated masses, such as switches.

High-frequency currents Due to the skin effect, only thin Cu coatings are required to achieve a conductivity corresponding to solid copper. This leads to the use in capacitors and components for transmission and receiving systems.

Did we convince you?